Introduction:

In industrial processes, having the right equipment is important. It comes to monitoring fluid flow, sight flow indicators play a important role. However, with various options available like flanged sight glass flow indicators, stainless steel flow indicators and Double Window Sight Glass, choosing the right one can be fix to process. This comprehensive guide will walk you through everything you need to know about selecting the perfect sight flow indicator for your specific requirements.

Your Guide to Choosing the Right Sight Flow Indicator

To select proper sight flow indicator is key for ensuring efficient operation and accurate monitoring of fluid flow within process. Here’s a detailed information to help you make an informed decision:

Flanged Sight Glass Flow Indicator

Flanged sight glass flow indicators offer robust construction and easy installation, making them ideal for high-pressure applications. With their clear glass window, they provide excellent visibility of fluid flow, enabling operators to monitor processes effectively.

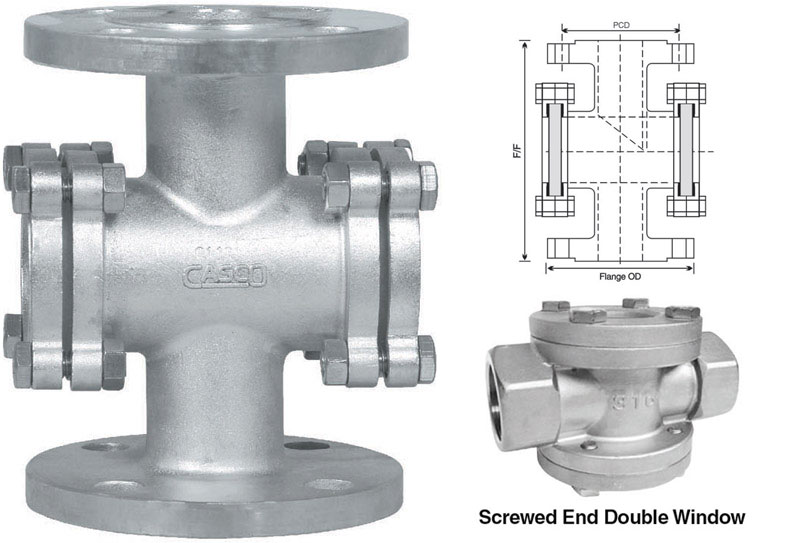

Double Window Sight Flow Indicator

Double window sight flow indicators feature two glass windows, allowing for observation from multiple angles. This design enhances visibility and facilitates inspections, making it easier to detect any anomalies in fluid flow.

Full View Sight Glass

For applications requiring maximum visibility, full view sight glasses are the perfect choice. These indicators provide an unobstructed view of the fluid flow, ensuring operators can easily monitor processes without any blind spots.

Glass Flow Indicator

It’s versatile and suitable for a wide range of applications. Because durable glass construction, Its offers excellent resistance to corrosion and harsh chemicals, making them suitable for various industries.

Level Indicator Sight Glass

It’s specifically designed for monitoring fluid levels in tanks and vessels. Featuring clear markings, it provides accurate level readings, allowing operators to maintain optimal fluid levels for efficient operation.

Pipe Flow Indicator

Pipe flow indicators are designed to fit directly into pipelines, Allows real-time monitoring of fluid flow. With its compact design and easily integrated into existing piping systems without extensive modifications.

Sight Flow Glass Indicator

Sight flow glass indicators, equipped with high-quality glass windows that offer exceptional clarity and durability. With its corrosion-resistant material, it allows reliable performance in demanding environments. Also available screweed end double window.

Stainless Steel Flow Indicator

Stainless steel flow indicators are known for their durability and corrosion resistance, making them suitable for harsh operating conditions. With their rugged construction, they offer long-term reliability and performance.

FAQs

How do I choose the right sight flow indicator for my application?

Are sight flow indicators suitable for high-pressure applications?

Can sight flow indicators be used with corrosive fluids?

How do I install a sight flow indicator?

What maintenance is required for sight flow indicators?

Can sight flow indicators be customized to meet specific requirements?

Conclusion

Selecting the perfect sight flow indicator isn’t just about a clear view – it’s about optimizing your process. By considering factors like operating pressure, visibility needs, and fluid type, you ensure accurate flow monitoring and peak efficiency. Whether you choose a flanged, stainless steel, or custom-designed indicator, a reliable manufacturer is key for long-lasting performance and peace of mind.